#Numerical Simulation in Aerospace

Explore tagged Tumblr posts

Text

#Computational Fluid Dynamics#Aerospace Engineering#Aeroacoustics#Aerospace Propulsion#Aerodynamic Analysis#CFD Applications in Aerospace#Shock-Boundary Layer Interaction#Aeroelastic Analysis#Combustion Modeling#High-Speed Flow Analysis#Turbofan Engine Simulation#Drag Reduction Techniques#Aerospace Vehicle Design#Numerical Simulation in Aerospace#Flow Field Optimization

0 notes

Text

'Sloshing' from celestial collisions solves mystery of how galactic clusters stay hot

The XRISM collaboration has discovered flows of hot gas in the core of the Centaurus Cluster. By comparing state-of-the-art X-ray measurements from the XRISM satellite with numerical simulations, they showed this is evidence for collisions between galaxy clusters, causing gas inside to "slosh." This solves the longstanding mystery of how cluster cores stay hot, and sheds light on how our universe continues to evolve.

Astronomers have long envisioned how vast gravitational forces between galaxies and galactic clusters, colossal cosmic assemblies bound by dark matter, drive their growth through mergers and collisions. However, direct evidence for this has been lacking.

The international XRISM (X-ray Imaging and Spectroscopy Mission) collaboration has observed the Centaurus galaxy cluster with the XRISM satellite, launched in 2023 by the Japan Aerospace Exploration Agency (JAXA); the on-board spectrometer, called Resolve, features groundbreaking precision spectroscopy, allowing accurate identification of gas velocities.

Looking at the core of the Centaurus Cluster, including the central galaxy NGC 4696, they discovered for the first time a bulk flow of hot gas traveling about 130 to 310 kilometers per second in the line-of-sight from Earth. They were also able to create a map of how the velocity varies at locations away from the center.

Making comparisons with simulations, a task team led by Professor Yutaka Fujita from Tokyo Metropolitan University and Associate Professor Kosuke Sato from the High Energy Accelerator Research Organization found that this is consistent with the "sloshing" of the hot gas, also known as the intracluster medium (ICM), caused by collisions with other galactic clusters. This is the first direct evidence for this kind of sloshing, validating a long-hypothesized picture of the evolution of the universe.

It also solves a long-standing mystery for astronomers about how such bright X-ray-emitting gas stays hot. Theoretically, such intense radiation should entail a loss of energy, leading to cooling of the gas; this is known as radiative cooling. The time scale over which this cooling should occur is shorter than the age of the cluster, but observations so far suggest that, somehow, the gas manages to stay hot.

These new findings present an elegant solution to this problem. If the gas in the cluster core can slosh, involving vast bulk flows of gas to-and-fro around the center, energy can be transported to the core through a mixing process, keeping the gas hot and the emissions bright. The team's results have now been published in the journal Nature.

These unprecedentedly precise measurements are a significant leap forward in our understanding of the formation and evolution of galactic clusters. With years still left in the XRISM mission, the world of astrophysics eagerly awaits more insights into the changing nature of the universe.

TOP IMAGE:Artist's impression of the center of the Centaurus Cluster. Blue shows a vast flow of hot gas, white shows galaxies, and reddish brown shows cool gas. Credit: JAXA

CENTRE IMAGE:X-ray spectrum of the Centaurus Galaxy Cluster measured with the XRISM Resolve spectrometer. The spectrometer on the XRISM satellite can tell peaks apart with unparalleled resolution. Credit: JAXA

LOWER IMAGE:Schematic of measurement by XRISM. Galaxy NGC 4696 at the center of the cluster is surrounded by different gas flows on either side with respect to our line of sight. Credit: JAXA

BOTTOM IMAGE:Intergalactic "sloshing" of hot gas. Collisions between clusters generate a "sloshing" effect for the intracluster medium, causing vast flows of gas that cause the content of the clusters to oscillate. Credit: JAXA

2 notes

·

View notes

Text

What is a DC Load Bank Used For?

Unmasking the Powerhouse Behind Your Devices

In the bustling world of electricity, where power generation, transmission, and distribution are the lifeblood of modern living, there exists a lesser-known yet indispensable component: the DC load bank. While it might not be a household name, its role in ensuring the reliability and efficiency of power systems is paramount. Let’s dive into the world of DC load banks and uncover their significance.

What Exactly is a DC Load Bank?

Think of a DC load bank as a diligent workout buddy for your power sources. It’s essentially a device engineered to simulate electrical loads for direct current (DC) power sources. Composed of resistive elements that transform electrical energy into heat, it effectively draws power from the system under test. While this might sound simple, its applications are vast and crucial.

Why Do We Need DC Load Banks?

The primary purpose of a DC load bank is to assess and evaluate the performance of DC power sources. This includes:

Battery Testing: Batteries are the heart of numerous DC systems, from electric vehicles to uninterruptible power supplies (UPS). Regular testing is crucial to ensure they can deliver the required power when needed. DC load banks mimic real-world conditions, allowing for precise evaluation of battery capacity, discharge rate, and overall health.

UPS Testing: UPS systems provide backup power during outages. Load banks simulate heavy loads, mirroring real-world scenarios and helping determine if the UPS can handle the demand.

Generator Testing: Even though generators primarily produce AC power, they often have DC systems for control and excitation. DC load banks can be used to test these components.

Rectifier Testing: Rectifiers convert AC to DC power. Load banks aid in evaluating their performance and efficiency.

Research and Development: In laboratories and research facilities, DC load banks are used to test new battery technologies, power electronics, and other DC systems.

Real-World Applications

To grasp the importance of DC load banks better, let’s explore some real-world examples:

Data Centers: Data centers heavily rely on UPS systems to shield critical IT equipment from power outages. Regular load testing using DC load banks is crucial to ensure the UPS can handle the load and prevent costly downtime.

Renewable Energy: Solar and wind power systems often incorporate battery storage. Load banks are used to test the performance and capacity of these batteries.

Electric Vehicles: Battery electric vehicles (EVs) are gaining popularity. Manufacturers employ DC load banks to test the performance and longevity of EV batteries under various conditions.

Military and Aerospace: In these sectors, reliable power is paramount. DC load banks are used to test batteries, power supplies, and other DC equipment in harsh environments.

EMAX Load Bank: A Powerhouse Solution

EMAX Load Bank specializes in providing top-tier DC load bank solutions. With a commitment to quality and innovation, EMAX offers a range of load banks tailored to meet diverse industry needs. From compact units for research to heavy-duty solutions for industrial applications, EMAX has you covered.

youtube

Benefits of Using DC Load Banks

Enhanced Reliability: Regular testing with a DC load bank helps identify potential issues before they lead to system failures.

Increased Efficiency: By accurately assessing power system performance, load banks help optimize energy usage.

Extended Equipment Lifespan: Proper maintenance, enabled by load bank testing, can prolong the life of batteries and other components.

Compliance: Many industries have regulations requiring regular testing of power systems. DC load banks help ensure compliance.

Cost Savings: Preventing unexpected failures and maximizing equipment lifespan can result in significant cost savings.

Conclusion

DC load banks, though often overlooked, are the unsung heroes of power systems. By simulating real-world conditions, they provide invaluable data for testing, troubleshooting, and optimizing performance. As our reliance on DC power continues to grow, the importance of load banks will only increase.

2 notes

·

View notes

Link

On May 16, 2024, a crowd of more than 500 people gathered at Space Center Houston’s IMAX theater for the Expedition 70 crew debrief and awards ceremony. Crew members from NASA’s SpaceX Crew-7 and Soyuz MS-24 missions shared reflections from their voyage aboard the International Space Station and bestowed well-deserved recognition upon Johnson Space Center employees and partners whose dedication and support contributed to the expedition’s success. A group photo of participants from the Expedition 70 crew debrief and awards ceremony on May 16, 2024, at Space Center Houston’s IMAX theater. Credit: NASA/David DeHoyos The special event featured four Expedition 70 astronauts: Jasmin Moghbeli, Crew-7 commander and Expedition 70 flight engineer, NASA Loral O’Hara, Soyuz MS-24 and Expedition 70 flight engineer, NASA Andreas Mogensen, Crew-7 pilot and Expedition 70 commander, ESA (European Space Agency) Satoshi Furukawa, Crew-7 mission specialist and Expedition 70 flight engineer, JAXA (Japan Aerospace Exploration Agency) NASA astronaut Stephen Bowen kicked off the event by striking the ceremonial bell to complete the 70th voyage to the orbiting laboratory. Johnson Deputy Director Stephen Koerner honored the crew’s achievements. “Through the Johnson Space Center’s Dare | Unite | Explore initiatives, we are called to unite with our partners to complete these bold missions,” said Koerner. “Tonight, we are celebrating the completion of one of those such missions.” NASA’s SpaceX Crew-7 crew inside the vestibule in between the SpaceX Dragon Endurance spacecraft and the International Space Station’s Harmony module. From left are Roscosmos cosmonaut Konstantin Borisov, ESA (European Space Agency) astronaut Andreas Mogensen, NASA astronaut Jasmin Moghbeli, and JAXA (Japan Aerospace Exploration Agency) astronaut Satoshi Furukawa. Credit: NASA The Crew-7 mission was the first in the history of the Commercial Crew Program to have each seat in the Dragon spacecraft occupied by a different international partner. The Expedition 70 crew successfully conducted 286 experiments and received five cargo resupply missions that delivered thousands of pounds of scientific research, supplies, and hardware to the orbital outpost. The astronauts performed numerous science experiments and technology demonstrations, including the first robotic surgery (on simulated tissue) in space. The crew also encountered several other notable firsts. O’Hara and Moghbeli undertook their inaugural spacewalk together, while ESA astronaut Andy Mogensen became the first non-US pilot to fulfill that role on the Dragon vehicle. The crew also welcomed the third private astronaut mission, Ax-3, aboard the orbiting laboratory, along with Marina Vasilevskaya, the first female Belarusian in space as a spaceflight participant. “Even after more than 25 years of operations, we continue to experience exciting firsts aboard station,” said Dana Weigel, program manager for the International Space Station Program. “On behalf of the ISS Program, I want to thank the crew and the ground teams around the world for your passion and commitment to the International Space Station mission. The incredible advancements we make that benefit life here on Earth and inspire future generations are a direct result of your work.” Watch below to recap the Expedition 70 crew members’ unique journey aboard the International Space Station and to celebrate those who helped make the mission a success.

2 notes

·

View notes

Text

February 2024 Update - Kaf & the Octonauts

Hello everyone. This is your host Kaftan von Kaffeeklatsch and you're listening to the Cosmic Millipede Podcast, the show about rocket ships, red quasars, and the search for extraterrestrial life. Before getting to today's interview, I'd like to apologize for the delay since our last episode. We've been quite busy preparing content for the new year, so it took more time than expected.

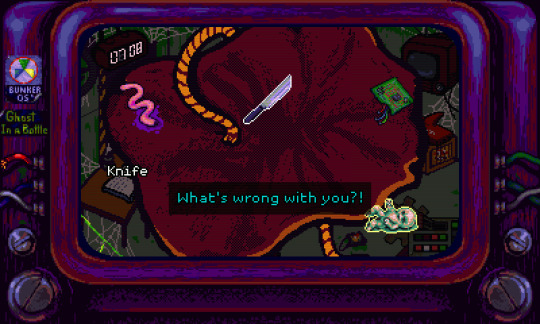

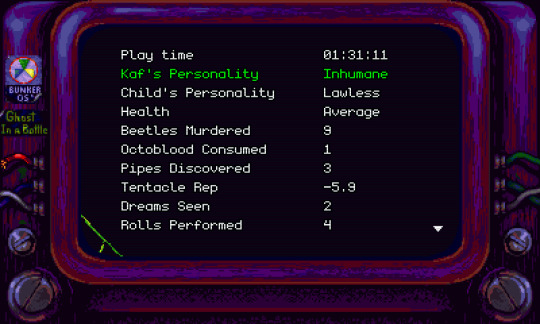

Today's sponsor is the Ghost in a Bottle Consortium. Do check out their upcoming Octopus City Simulation that's coming soon. You can already download a lengthy demo on Steam, itch.io or GOG. Oh, and if you're reading the transcript after the episode, we took the liberty of adding the latest Octopus City Blues screenshots for you to admire.

Our guest today needs no introduction. I'm talking about the infamous business tycoon, the world's wealthiest person, and the founder of Kosmomash Rockets, Constantin Mandibule. Unless you've been living under a rock for the last ten years, I'm sure you're familiar with Kosmomash's long-awaited projects: the first privately-developed rocket to carry tourists to the moon, and the ambitious luxury resort they're building over there.

Monsieur Constantin Mandibule, thank you for taking time out of your busy schedule to have this chat.

It's my pleasure, Kaftan. And please, there's no need for formalities. Just call me ConMan—all my friends do.

Uh… all right, Monsieur Conman. Last year was a very important one for Kosmomash, wasn't it?

Absolutement! It was also different—much more business-focused than previous years. Between showcasing our rocket prototypes publicly and at industry events, talking to potential partners, and onboarding new talent, comparatively less time was spent on developing rocket components. These activities were all essential for establishing a strong promotional foundation for this year's big launch. With that out of the way, we are currently back to focusing on construction.

How exciting! The prototype you unveiled during the Next Fest Aerospace Convention caused quite a stir among the attendees. Could you tell us more about it?

What I can tell you, Kaftan, is that it took a lot of hard work to finally get the prototype out the door. It was useful preparation for our final launch, too. For example, working with STEAM's [Editor's Note: Space Tourism Enforcement And Monitoring agency] launch regulations and cloud computing infrastructure forced us to optimize our release processes.

The feedback we received from the attendees was extremely valuable as well; while some of the casualties were avoidable, we continue to learn from every tragedy. Au fait, we just published a new version of our prototype specs a couple of weeks ago, fixing many issues encountered by real users in the wild.

The accidents were regrettable, but the altar of technology demands its sacrifices. What are some of the lessons learned from the launch of the prototype?

Euh… much of it has to do with improving the user experience. For example, our DAISY module is programmed to react to the needs of space tourists. However, as post-war treaties ban the use of AI, we have to manually write responses to every potential user query. Watching so many lab ra—err, people, try the demo helped us identify hundreds of new DAISY responses.

Another finding from the handful of unfortunate incidents was that the control systems were not very intuitive to first-time users. As the average space tourist isn't a trained pilot, we had to place large signs all over the space module—really obvious warnings such as "Keep the windows closed after launch", "Repeatedly press the red button to breathe", or "Carefully arrange the fusion matrix stack if the gradient is inverted".

There were, en outre, numerous fixes and rocket engine performance improvements. We also introduced two new cockpit views to track the current flight status: the Facts And Figures screen displays various metrics during and at the end of the trip, while the Calendar App keeps track of all the space debris collected along the flight path.

That's very interesting. The prototype must be much safer now, especially compared to the versions you tested at the INDIGO SKIES and SpaceAdventureX events last year.

Tout à fait! And let's not forget the Independent Rocketry Showcase, the Test & Fly event, and the numerous people who tried our prototype rocket kit at home and streamed it online. We're really thankful to everyone who got injured to get us closer towards uncovering the dark mysteries of the great beyond.

And closer to lining your pockets, no doubt. Moving on, you mentioned hiring new colleagues.

Oui, c'est juste. People are surprised when I say this, Kaftan, but I've been writing all of the company's press releases from the very beginning. I simply enjoy doing it! laughs. English is obviously not my mother tongue, and so a lot of mistakes were made. Thankfully, we now have a professional editor, Julia Seeholzer, to help us sort out all the there's, theirs, and they'res!

More recently, Shannon Mason, the celebrated composer also known as Pongball, has joined the team, and is already working on some exciting tunes. Some of these will be played during the long elevator rides to the underground mines beneath the lunar resort. Manual space labor doesn't have to be boring, after all!

Are we still talking about space tourists? Anyway, with all the feedback, exposure, and new colleagues, it sounds like you're on target for this year's big launch. What are you working on these days?

Like I said, the focus is finally back to developing new things. Last year we worked on a western themed area in the planned resort. We're wrapping that up while also constructing a magnificent coliseum and an underwater village. There's a lot going on behind the scenes that we can't talk about yet. We want it to be une grande surprise for our precious guests.

As for the planned launch, it's still going according to plan, and we're doing our best to meet our summer targets. With that said, the prototype showed us that no matter how much testing we do, actual users will keep uncovering all the bugs… I mean, easter eggs, we intentionally add. Quality Assurance remains the biggest unknown at the moment.

On the other hand, we've invested in a very solid foundation over the years, and everyone's doing their best to finally give humanity the salvation it so desperately needs. One way or another, I'm confident that this year is the year of Kosmomash. After all, we only need to ensure that half the tourists actually make it to the moon. How hard can it be?

Who knows? It's not like we're talking about rocket science or anything. In any case, thank you, Monsieur Conman, for your valuable time, and good luck with your ambitious plans for this year. I hope we get to talk again after the first batch of tourists make it to the moon.

Moi aussi! Thank you for having me, Herr Kaftan.

#octopus city blues#pixel art#pixelart#gamedev#adventure game#indie game#update#devlog#news spin#moon#news

5 notes

·

View notes

Text

CNC Milling: The Core of High-Precision Manufacturing

Introduction

The CNC milling process is a fundamental technique in precision machining, enabling manufacturers to create high-quality components with minimal human intervention. By utilizing computer numerical control (CNC) technology, milling machines shape materials such as metal, plastic, and wood into intricate designs with exceptional accuracy. In this blog, we explore the fundamentals of CNC milling, its advantages, and key applications across industries.

What is CNC Milling?

CNC milling is a subtractive manufacturing process that removes material from a solid workpiece using rotating cutting tools. Unlike manual milling, CNC milling is automated, following pre-programmed G-code instructions to achieve precise dimensions and complex geometries.

Key Features of CNC Milling

Multi-Axis Control �� Operates on 3-axis, 4-axis, or 5-axis configurations for intricate designs.

High Precision – Achieves tolerances as tight as ±0.001 inches.

Versatile Material Compatibility – Works with metals, plastics, composites, and wood.

Automated Efficiency – Reduces human error and speeds up production.

Advantages of CNC Milling

1. Exceptional Accuracy and Consistency

CNC milling ensures repeatable precision, making it ideal for industries requiring tight tolerances:

Aerospace Components – High-precision parts for aircraft and spacecraft.

Medical Devices – Surgical instruments and prosthetics with intricate details.

Automotive Parts – Engine components and custom vehicle parts.

2. Increased Production Efficiency

Automated CNC milling enhances manufacturing speed:

Rapid Prototyping – Quickly produces prototypes for testing.

Mass Production – Scales up production with minimal waste.

Reduced Labor Costs – Minimizes manual intervention.

3. Complex Geometries and Customization

CNC milling allows for intricate designs that manual machining cannot achieve:

3D Contouring – Smooth curves and detailed engravings.

Multi-Surface Machining – Works on multiple angles and depths.

Custom Tooling – Adapts to unique project requirements.

Applications of CNC Milling

1. Aerospace and Automotive Industries

CNC milling is essential for high-performance components:

Aircraft Frames and Engine Parts – Lightweight, durable materials.

Automotive Prototypes – Custom designs for testing and production.

2. Medical and Electronics Manufacturing

Precision machining supports advanced medical and electronic devices:

Implants and Prosthetics – Biocompatible materials for healthcare.

Circuit Boards and Casings – High-precision parts for electronics.

3. Industrial and Consumer Goods

CNC milling is widely used in custom manufacturing:

Machinery Components – Gears, brackets, and housings.

Furniture and Decorative Items – Wood and metal engravings.

How to Optimize CNC Milling for Your Project

1. Choose the Right Material

Select materials based on strength, durability, and machinability:

Aluminum and Titanium – Lightweight and corrosion-resistant.

Plastics and Composites – Ideal for electronics and medical applications.

2. Optimize Tooling and Cutting Parameters

Enhance efficiency with proper tool selection:

End Mills and Face Mills – Different tools for varied surface finishes.

Cutting Speed and Feed Rate – Adjust settings for precision and efficiency.

3. Utilize Advanced CNC Software

Improve accuracy with CAD/CAM integration:

3D Modeling and Simulation – Ensures design feasibility.

Automated Toolpath Generation – Reduces programming time.

Conclusion

The CNC milling process is a powerful, precise, and efficient manufacturing method used across industries. Whether producing aerospace components, medical devices, or industrial machinery, CNC milling offers high-quality results with minimal waste. Investing in advanced CNC technology ensures cost-effective production, superior accuracy, and limitless customization.

0 notes

Text

How CNC Engineering Services Are Revolutionizing Manufacturing

In today's fast-paced industrial era, innovation and precision are more important than ever. As traditional manufacturing methods struggle to meet the growing demand for accuracy, speed, and customization, CNC engineering services have stepped in as a game-changer. From aerospace and automotive to medical and consumer goods, computer numerical control (CNC) technology is reshaping how products are designed, developed, and delivered. One standout leader in this space is MS Machining, a company at the forefront of precision manufacturing solutions.

What Are CNC Engineering Services?

CNC engineering services involve the use of computer-controlled machines to carry out various manufacturing tasks such as milling, turning, drilling, and cutting. These machines follow pre-programmed designs with extreme precision, minimizing human error and maximizing repeatability. Instead of relying on manual labor or conventional tools, CNC machines are guided by CAD (Computer-Aided Design) and CAM (Computer-Aided Manufacturing) software to execute intricate processes with unmatched efficiency.

The Key Drivers Behind the CNC Revolution

The rise of CNC engineering services can be attributed to several industry-wide needs and challenges. Below are the major drivers:

1. Demand for Precision

CNC machines can achieve tolerances within thousandths of an inch. For industries like aerospace or medical, where even the smallest error can lead to catastrophic failure, this level of precision is non-negotiable. Companies like MS Machining have built a reputation for delivering consistent accuracy, making them trusted partners in high-stakes manufacturing environments.

2. Faster Turnaround Times

With traditional methods, producing a single component could take days or even weeks. CNC engineering dramatically reduces production time, especially for prototypes and small-batch runs. Using automated processes, manufacturers can quickly switch between designs, allowing for agile production cycles.

3. Cost Efficiency

While CNC machines require an upfront investment, they reduce long-term costs through automation, reduced material waste, and minimized labor costs. Once the machine is programmed, it can run 24/7 with minimal supervision, significantly boosting productivity.

4. Customization and Flexibility

Modern markets demand customization. CNC services enable the easy alteration of product designs without retooling machinery, offering unparalleled flexibility. Whether it’s producing bespoke medical implants or custom automotive parts, CNC engineering opens the door for personalized production at scale.

Core Advantages of CNC Engineering Services

CNC engineering services are not just an improvement over manual processes; they represent a fundamental shift in how manufacturing is approached.

● Enhanced Productivity

CNC machines can work continuously without fatigue. This allows businesses to increase their output while maintaining consistent quality. With expert CNC service providers like MS Machining, clients receive a streamlined production process from design to final product.

● Improved Safety

Manual machining involves high-risk tasks like cutting and drilling. With CNC automation, human operators are removed from direct contact with hazardous equipment, creating a safer work environment.

● Scalability

Whether producing a one-off prototype or scaling to thousands of units, CNC engineering services offer the scalability to grow with your business needs. The ability to replicate high-precision components ensures smooth transitions from small batches to mass production.

● Integration with Modern Technologies

CNC services seamlessly integrate with other digital tools such as 3D modeling, simulation software, and IoT-enabled sensors. This integration promotes smart manufacturing, where machines self-monitor, optimize performance, and even predict maintenance needs.

CNC Engineering Across Industries

The reach of CNC technology spans nearly every sector:

■ Aerospace

The aerospace industry requires components that can withstand extreme conditions. CNC machining ensures parts like turbine blades and engine housings meet exacting standards for strength, weight, and durability.

■ Automotive

From engine blocks to gearboxes, CNC machines are integral to producing reliable and high-performance automotive components. CNC also allows for quicker model transitions, ideal for the fast-moving auto market.

■ Medical

Precision is critical in medical device manufacturing. CNC engineering allows for the production of implants, prosthetics, and surgical tools with micron-level accuracy, reducing risk during surgeries and improving patient outcomes.

■ Consumer Electronics

As devices become smaller and more complex, CNC machining enables the production of detailed housings and circuit board components essential for modern electronics.

MS Machining: Precision at Its Best

When discussing the revolution in CNC engineering, it’s impossible to ignore companies like MS Machining. With years of industry experience and a state-of-the-art facility, MS Machining exemplifies the benefits of CNC technology. They specialize in both rapid prototyping and full-scale production runs, serving a wide range of sectors with a strong emphasis on quality, consistency, and innovation.

What Sets MS Machining Apart?

Advanced Machinery: MS Machining utilizes the latest CNC milling, turning, and multi-axis systems to meet complex client needs.

Experienced Team: Their skilled engineers and machinists ensure each project is handled with technical expertise and attention to detail.

Quality Assurance: From first-piece inspections to full batch testing, MS Machining has strict quality protocols in place.

Customer-Centric Approach: They work closely with clients from the design phase through final production, ensuring every specification is met.

Whether you're developing a prototype for a new medical device or scaling production for an automotive component, MS Machining provides the engineering support and CNC capabilities to bring your vision to life.

The Future of CNC Engineering

Looking ahead, CNC engineering services will only become more integral to manufacturing. Emerging trends like AI integration, predictive maintenance, and real-time monitoring will push CNC capabilities even further. Smart CNC systems will not only execute commands but adapt in real-time for improved output and reduced downtime.

Additive manufacturing (3D printing) is also beginning to complement CNC services, particularly for complex geometries. Hybrid systems combining CNC machining and 3D printing are already under development, promising even more efficient and flexible production.

Conclusion

CNC engineering services are at the core of the manufacturing revolution—delivering precision, speed, cost savings, and adaptability across every industry. The shift from manual labor to automated precision has made it possible to produce higher-quality products in less time, and with fewer resources.

Leading the way in this transformation is MS Machining, a brand that epitomizes innovation, reliability, and precision. As manufacturers worldwide look to stay competitive in an increasingly digital and global market, CNC services will continue to play a central role—and partnering with a trusted provider like MS Machining is the key to staying ahead of the curve.

0 notes

Text

Aluminum Prototype Manufacturing By Sanwometal

In recent times' speedy-paced product development internationally, developing practical prototypes speedy and effectively is essential. Aluminum Prototype Manufacturing stands out as a well-known preference for engineers and architects aiming to validate requirements earlier than mass production. This manner combines the mild-weight, long lasting nature of aluminum with advanced manufacturing strategies to provide specific prototypes that carefully mimic the very last product.

Why Choose Aluminum for Prototyping?

Aluminum is one of the maximum bendy metals implemented in production due to its amazing electricity-to-weight ratio, corrosion resistance, and machinability. These houses make it first-class for prototypes that need to be slight-weight but long lasting. Unlike plastic prototypes, aluminum prototypes can face up to mechanical testing, warmness exposure, and are located on, allowing designers to evaluate real-international regular performance.

Moreover, aluminum’s awesome thermal and electric conductivity may be important for prototypes in electronics, automobile, and aerospace industries, wherein warmth dissipation and electric powered grounding are critical.

Methods of Aluminum Prototype Manufacturing

Several manufacturing techniques are used to create aluminum prototypes, each imparting distinct benefits counting on the mission requirements:

CNC Machining

CNC (Computer Numerical Control) machining is the most unusual technique for aluminum prototype manufacturing. It involves the use of precision reducing gear controlled through the way of computer packages to form aluminum blocks into the desired shape. CNC machining gives splendid accuracy and ground cease, making it ideal for complex geometries and tight tolerances. Additionally, it lets in short turnaround instances, assisting speedy new launches at a few degrees within the format segment.

3-D Printing (Additive Manufacturing)

While 3-D printing of aluminum remains growing, selective laser melting (SLM) and direct metal laser sintering (DMLS) can create complex aluminum prototypes layer-thru-layer. These strategies are beneficial for intricate inner capabilities or moderate-weight lattice structures that traditional machining can't results easily gain. However, three-D published aluminum additives regularly require placed up-processing to beautify ground quit and mechanical homes.

Die Casting and Investment Casting

For prototypes that require production-like manufacturing conditions, die casting or investment casting may be used. These techniques pour molten aluminum into molds to create genuine prototypes that simulate the final production additives. They are extra appropriate for medium to massive batch prototyping due to the fees concerned in mildew creation.

Advantages of Aluminum Prototype Manufacturing

Durability and Strength: Aluminum prototypes can go through functional testing that mimics give up-use conditions, such as strain, impact, and environmental publicity.

Lightweight: Ideal for merchandise requiring portability or reduced weight, together with drones, purchaser electronics, and vehicle additives.

Excellent Machinability: Aluminum machines are faster and less complicated than many one in all a kind metals, reducing lead instances.

Corrosion Resistance: Aluminum evidently forms an oxide layer, shielding prototypes from corrosion at some point of dealing with and trying out.

Reusability: Aluminum scrap from prototyping can regularly be recycled, contributing to sustainable manufacturing practices.

Applications of Aluminum Prototypes

Aluminum Prototypes are appreciably used within the direction of industries, which encompass aerospace, automobile, clinical devices, customer electronics, and industrial machines. Whether it’s a casing for a brand new system, a component for an engine, or a systematic device, aluminum prototyping facilitates finding out layout flaws early, refine ergonomics, and validate manufacturing feasibility.

Conclusion

Aluminum Prototype Manufacturing in China is a powerful approach that bridges the distance among concept and production. By supplying speedy, long lasting, and accurate prototypes, it empowers engineers to innovate with a bit of luck and reduce time-to-marketplace. As production technology keeps to comply, aluminum will stay a cornerstone cloth for prototyping, blending basic standard overall performance with flexibility.

0 notes

Text

CNC Turning Services India

Introduction to CNC Turning Services

What is CNC Turning?

CNC turning is one of the most precise and efficient manufacturing techniques available today. At its core, CNC (Computer Numerical Control) turning is a subtractive machining process where a cutting tool removes material from a rotating workpiece. This technique is commonly used to create cylindrical parts and is controlled by pre-programmed computer software. Unlike manual machining, CNC turning enables extreme precision and repeatability, making it ideal for high-volume production and intricate designs.

Imagine trying to carve a perfect cylinder out of metal using just your hands—tough, right? That’s where CNC turning comes in. It's like using a super-smart robot arm that follows digital instructions down to the last micron. Whether it’s producing bolts, screws, engine components, or delicate aerospace parts, CNC turning ensures every item meets exact specifications.

This method supports a wide range of materials, from simple aluminum to more complex alloys, enabling industries to innovate and manufacture with unparalleled consistency and quality.

Importance of CNC Turning in Modern Manufacturing

In today’s fast-paced industrial world, precision isn’t just a luxury—it’s a necessity. From automotive engines to medical implants, even the smallest component must function flawlessly. That’s where CNC turning Services India. It guarantees precision, consistency, and scalability that manual processes simply can’t match.

Why is this important? Think about your car’s engine. Every tiny part needs to be perfectly made or you risk the whole machine breaking down. CNC turning allows manufacturers to produce complex geometries at lightning speed without compromising accuracy.

Moreover, the integration of digital technology into machining has opened up a world of possibilities. Engineers can now simulate processes, reduce errors, and streamline production lines—all thanks to the power of CNC turning.

This technique also supports lean manufacturing principles. With minimal waste, quick turnaround times, and automation, it helps businesses stay competitive while adhering to sustainability goals. Whether it's prototyping or full-scale production, CNC turning is at the heart of modern manufacturing.

Overview of CNC Turning Industry in India

Growth and Expansion of CNC Services in India

India has rapidly emerged as a global hub for CNC machining, and CNC turning is a big part of that success story. Over the past decade, the Indian CNC turning industry has grown significantly, fueled by rising demand from domestic sectors and global markets. Factors like Make in India initiatives, growing foreign investments, and advancements in infrastructure have all contributed to this boom.

Walk through any industrial corridor in India, and you'll find modern CNC shops humming with activity. These are not just job shops—they’re highly organized, tech-savvy businesses catering to industries ranging from automotive to aerospace. According to market analysts, India's CNC machining market is expected to grow by over 7% CAGR between 2024 and 2029.

Part of this growth comes from India's ability to offer a cost-effective yet high-quality solution to global clients. Thanks to the country's rich engineering talent pool and relatively lower operational costs, Indian CNC turning services are in high demand across Europe, North America, and Asia-Pacific.

The shift towards automation and digitization is also accelerating the expansion. Indian manufacturers are investing in high-end CNC machines, robotic arms, and CAD/CAM integration to stay ahead in the global race.

Key Sectors Utilizing CNC Turning in India

CNC turning services are deeply integrated into multiple key sectors across India:

Automotive: India is one of the largest automotive manufacturing hubs in the world. CNC turning is used extensively to produce engine parts, gear components, brake systems, and custom hardware.

Aerospace: From satellite components to aircraft engine parts, CNC turning ensures the extreme precision required in this high-stakes sector.

Medical Devices: CNC turning plays a vital role in crafting surgical tools, orthopedic implants, and dental equipment with unmatched accuracy.

Defense and Military: High-grade components used in weaponry, communication systems, and armored vehicles are all products of CNC turning.

Electronics and Telecommunications: This includes connectors, heatsinks, and enclosures that require tight tolerances and exact dimensions.

India’s diversified industrial base, combined with its technical capabilities, makes it a go-to destination for precision CNC turned components.

Advantages of Choosing CNC Turning Services in India

Cost-Effectiveness and Affordability

One of the biggest reasons companies outsource CNC turning to India is cost-effectiveness. Let’s face it—precision manufacturing in Western countries often comes with a hefty price tag. But India offers a sweet spot: high-quality output at a fraction of the cost.

How’s that possible? Lower labor costs, competitive material sourcing, and optimized operations make Indian CNC service providers some of the most affordable in the world. And we're not talking cheap in quality—just in price. The best shops follow international standards like ISO, TS, or AS certifications, so you’re getting premium-grade components without draining your budget.

Another benefit? Many Indian companies offer flexible pricing models. Whether it’s prototyping, small batch production, or full-scale manufacturing, you can find a service package that fits your needs and budget.

Outsourcing to India also saves on infrastructure costs. You don’t need to invest in machinery, manpower, or maintenance. Just send your design files, and get the parts delivered to your door—fast, affordable, and efficient.

Skilled Workforce and Technical Expertise

India’s engineering education system churns out thousands of skilled professionals every year, and many of them specialize in CNC Turning Services India . From machine programmers to CAD/CAM designers, you’ll find a deep talent pool that knows how to get things done.

More importantly, Indian CNC shops don’t just follow instructions—they understand the "why" behind every cut. This means fewer errors, better optimization, and even design suggestions that can save you money and time.

Many technicians and operators are trained to work on state-of-the-art equipment. Whether it's 3-axis or 5-axis CNC lathes, Swiss-type turning, or robotic automation, the Indian CNC ecosystem is both skilled and future-ready.

And let’s not forget about language. English is widely spoken in the engineering and manufacturing sectors, making communication seamless and effective.

#CNC Turning Services India#CNC Machining Services India#CNC Milling Service India#Cold Forging Services India

0 notes

Text

3D Display Market Size, Share, Trends, Key Drivers, Growth, Challenges and Opportunity Forecast

Executive Summary 3D Display Market:

3D Display Market Market report can be explored in terms of breakdown of data by manufacturers, region, type and application, market status, market share, growth rate, future trends, market drivers, opportunities and challenges, emerging trends, risks and entry barriers, sales channels, and distributors. The report identifies the most recent improvements, market share, and systems applied by the significant market. Both established as well as new players in the industry can efficiently use this 3D Display Market Market report for absolute understanding of the market. The 3D Display Market Market report has been crafted in such a way that it proves to be the most suitable to your business needs.

This report uses the SWOT analysis technique for the assessment of the development of the most remarkable market players. In this 3D Display Market Market report, the market is also well analyzed on the basis of numerous regions. 3D Display Market Market report has CAGR value fluctuations during the forecast period of 2018-2025 for the market. Thus, for better decision making and thriving business growth, the data and information covered in this market report is very imperative. The 3D Display Market Market report is provided with the powerful insights and data that helps outshine the competition. The 3D Display Market Market report helps the firm in exploring new uses and new markets for its existing products and thereby, increasing the demand for its products.

Discover the latest trends, growth opportunities, and strategic insights in our comprehensive 3D Display Market Market report. Download Full Report: https://www.databridgemarketresearch.com/reports/global-3d-display-market

3D Display Market Market Overview

**Segments**

- By Type: The 3D display market can be segmented into volumetric display, stereoscopic display, and multi-view display. Volumetric display offers a 360-degree view of the object and is commonly used in medical imaging and aerospace applications. Stereoscopic display provides a 3D effect by showing different images to each eye, creating depth perception. Multi-view display, on the other hand, enables multiple users to view the 3D content from different angles simultaneously.

- By Technology: The market can be categorized based on technologies such as Digital Light Processing (DLP), Light Emitting Diode (LED), Organic Light Emitting Diode (OLED), and others. DLP technology uses micro mirrors to create images, providing high resolution and contrast. LED technology offers energy efficiency and bright displays. OLED technology delivers vibrant colors and faster response times, making it suitable for high-end applications.

- By Application: The 3D display market finds applications in various industries including gaming, automotive, healthcare, aerospace, and others. In gaming, 3D displays enhance the gaming experience by providing immersive visuals. In the automotive sector, 3D displays are used for navigation, entertainment, and driver assistance systems. Healthcare applications include medical imaging, surgery simulation, and patient education.

**Market Players**

- Sony Corporation: Sony is a key player in the 3D display market, offering a wide range of 3D TVs and monitors. The company focuses on innovation and product development to stay ahead in the market.

- LG Electronics Inc.: LG is another prominent player in the 3D display market, known for its innovative OLED technology. The company offers a diverse portfolio of 3D display products catering to different industries.

- Samsung Electronics Co., Ltd.: Samsung is a leading manufacturer of 3D displays, particularly in the consumer electronics segment. The company invests heavily in research and development to bring cutting-edge 3D display technologies to the market.

- Panasonic Corporation: Panasonic is a well-established player in the 3D display market, offering a range of 3D TVs and professional displays. The company focuses on sustainability and quality in its products.

- Sharp Corporation: Sharp is known for its expertise in display technologies, including 3D displays. The company's commitment to innovation and customer satisfaction sets it apart in the competitive market.

The global 3D display market is witnessing significant growth due to the increasing demand for immersive viewing experiences across various industries. Technological advancements, such as improved resolution and refresh rates, are driving the market further. As the adoption of 3D displays continues to rise, key players are focusing on product development and strategic partnerships to maintain their competitive edge in the market.

Another key trend shaping the 3D display market is the emphasis on sustainability and energy efficiency. With the growing concern for environmental conservation and energy consumption, manufacturers are developing eco-friendly 3D display solutions that consume less power and have a reduced carbon footprint. This trend not only aligns with global sustainability goals but also appeals to eco-conscious consumers, thereby driving the adoption of sustainable 3D display technologies.

Moreover, the market is witnessing strategic collaborations and partnerships among key players to leverage their combined expertise and resources for mutual growth and expansion. These partnerships enable companies to access new markets, enhance their product portfolios, and accelerate innovation in 3D display technologies. By joining forces, market players can address the evolving needs of customers and strengthen their competitive position in the dynamic 3D display market landscape.

Furthermore, the increasing adoption of 3D displays in the healthcare sector for applications such as medical imaging, surgical planning, and patient education is creating lucrative opportunities for market players. The advanced visualization capabilities offered by 3D displays enable healthcare professionals to gain better insights, improve diagnostic accuracy, and enhance patient outcomes. As the healthcare industry continues to prioritize digital transformation and innovation, the demand for high-quality 3D display solutions is expected to surge, presenting a promising growth trajectory for companies operating in this space.

Market players such as Sony Corporation, LG Electronics Inc., Samsung Electronics Co., Ltd., Panasonic Corporation, and Sharp Corporation play a significant role in shaping the competitive landscape of the 3D display market. These key players focus on innovation, product development, and strategic partnerships to stay ahead in the market and meet the increasing demand for immersive viewing experiences across industries. With a strong emphasis on sustainability, quality, and customer satisfaction, these companies strive to differentiate themselves and maintain their competitive edge in the market.

One of the emerging trends in the 3D display market is the integration of augmented reality (AR) and virtual reality (VR) capabilities, driving the demand for more interactive and immersive experiences in entertainment, education, and training sectors. This trend is reshaping the market by pushing for enhanced resolution, brightness, and color accuracy in 3D displays to meet the evolving needs of consumers. Additionally, the focus on sustainability and energy efficiency is gaining traction, with manufacturers developing eco-friendly solutions to align with global sustainability goals and appeal to eco-conscious consumers.

Strategic collaborations and partnerships among key players are also prevalent in the 3D display market, enabling companies to leverage their combined expertise and resources for mutual growth and expansion. By joining forces, market players can access new markets, enhance product portfolios, and accelerate innovation in 3D display technologies to address changing customer demands effectively. The increasing adoption of 3D displays in the healthcare sector presents lucrative opportunities for market players, with advanced visualization capabilities improving diagnostic accuracy and patient outcomes.

In conclusion, the global 3D display market is poised for significant growth propelled by technological innovations, industry partnerships, sustainability initiatives, and diverse applications across various sectors. Companies operating in this space are well-positioned to capitalize on emerging trends, drive innovation, and meet the evolving needs of consumers and industries worldwide. The convergence of AR/VR technologies with 3D displays and the industry's focus on energy efficiency and sustainability are reshaping the market landscape, paving the way for new opportunities and growth in the 3D display market.

The 3D Display Market Market is highly fragmented, featuring intense competition among both global and regional players striving for market share. To explore how global trends are shaping the future of the top 10 companies in the keyword market.

Learn More Now: https://www.databridgemarketresearch.com/reports/global-3d-display-market/companies

DBMR Nucleus: Powering Insights, Strategy & Growth

DBMR Nucleus is a dynamic, AI-powered business intelligence platform designed to revolutionize the way organizations access and interpret market data. Developed by Data Bridge Market Research, Nucleus integrates cutting-edge analytics with intuitive dashboards to deliver real-time insights across industries. From tracking market trends and competitive landscapes to uncovering growth opportunities, the platform enables strategic decision-making backed by data-driven evidence. Whether you're a startup or an enterprise, DBMR Nucleus equips you with the tools to stay ahead of the curve and fuel long-term success.

Key Questions Answered in This Report: –

How has this 3D Display Market Marketperformed so far and how will it perform in the coming years?

Which are the key product types available in this 3D Display Market Market?

Which are the major application areas in the3D Display Market Market?

What are the key distribution channels in the global 3D Display Market Market?

What are the key regions in this 3D Display Market Market?

What are the price trends?

What are the various stages in the value chain of this industry?

What are the key driving factors and challenges in the market?

Browse More Reports:

Global Anaerobic Digestion Market Global Amblyopia Drugs Market Global Alzheimer’s Disease Treatment Market Global Alloy Safety Valve Market Global Airway Management Device Market Global Airway Management Consumables Market Global Airport Interactive Kiosk Market Global Aircraft Lightning Protection Market Global Air Fryer Market Global Air Cushion Packaging Market Global AI Store Manager Tool Market Global Agent Based Virtual Machine Backup and Recovery Market Global Advanced Driver-Assistance Systems (ADAS) Market Global Active Spoiler Market Global Active Approximators Vascular Closure Device (VCDs) Market Global Acrodysostosis Treatment Market Global Achondrogenesis Market Global Achlorhydria Treatment Market Global 5G Processor Market Global 5G Enterprise Market

About Data Bridge Market Research:

An absolute way to forecast what the future holds is to comprehend the trend today!

Data Bridge Market Research set forth itself as an unconventional and neoteric market research and consulting firm with an unparalleled level of resilience and integrated approaches. We are determined to unearth the best market opportunities and foster efficient information for your business to thrive in the market. Data Bridge endeavors to provide appropriate solutions to the complex business challenges and initiates an effortless decision-making process. Data Bridge is an aftermath of sheer wisdom and experience which was formulated and framed in the year 2015 in Pune.

Contact Us: Data Bridge Market Research US: +1 614 591 3140 UK: +44 845 154 9652 APAC : +653 1251 975 Email:- [email protected]

Tag

3D Display Market Market Size, 3D Display Market Market Share, 3D Display Market Market Trend, 3D Display Market Market Analysis, 3D Display Market Market Report, 3D Display Market Market Growth, Latest Developments in 3D Display Market Market, 3D Display Market Market Industry Analysis, 3D Display Market Market Key Player, 3D Display Market Market Demand Analysis

0 notes

Text

How to Get Started with Computational Fluid Dynamics (CFD)

Have you ever watched water flow from a tap, or seen smoke swirl through the air, and wondered how engineers predict and simulate such movements? That’s exactly where Computational Fluid Dynamics (CFD) comes into play.

CFD is a powerful branch of fluid mechanics that uses computer simulations to analyze and predict how fluids behave under various conditions. If you’re an engineering student curious about design, aerodynamics, energy, or even biomedical applications, learning CFD can be a game-changer for your career. Let’s break down how you can get started with it, step by step.

What Exactly Is CFD?

Before diving into the how, let’s clear up the what.

CFD is the art and science of solving and analyzing fluid flows using numerical methods and algorithms. Instead of doing real-world experiments (which can be expensive and time-consuming), engineers use CFD to simulate fluid behavior digitally. This includes everything from how air flows around a car to how blood moves through arteries.

The core of CFD involves three main elements:

Pre-processing – setting up the problem, geometry, and mesh

Solving – applying equations to simulate the flow

Post-processing – analyzing and visualizing the results

Why Should You Care About CFD?

Good question. CFD isn’t just for aerospace engineers or scientists. It’s used across a variety of industries:

Automotive: Improving aerodynamics and fuel efficiency

Civil Engineering: Designing ventilation systems in tunnels

Biomedical Engineering: Simulating blood flow for stent design

Energy Sector: Analyzing wind patterns for turbine placement

In short, CFD is everywhere fluids exist—air, water, gas, even oil—and learning it makes you a valuable asset in industries that value precision and innovation.

What You Need to Get Started

Now, how do you actually start learning CFD? Here’s what I suggest:

1. Get a Strong Foundation in Fluid Mechanics

Before diving into simulation tools, make sure your basics are solid. Understand the fundamental equations—continuity, momentum, and energy. These are often taught in core mechanical or aerospace engineering courses.

If you're still deciding where to study, it helps to pick a college with a strong practical orientation. I was recently reviewing the curriculum at NMIET in Bhubaneswar, and noticed how they integrate hands-on labs with subjects like Thermodynamics and Fluid Mechanics. That kind of exposure can really help.

2. Learn the Mathematics Behind It

You don’t need to be a math genius, but you do need to be comfortable with:

Differential equations

Linear algebra

Numerical methods

These are the tools CFD software uses behind the scenes to simulate reality.

3. Get Familiar with CFD Software

There are many popular CFD tools available:

ANSYS Fluent

OpenFOAM (open-source)

COMSOL Multiphysics

SimScale (cloud-based)

Start with student versions or open-source platforms. OpenFOAM is great if you’re okay with some coding, while ANSYS Fluent offers a more visual, drag-and-drop interface.

4. Take Online Courses or Certification Programs

CFD can be complex, so guided learning really helps. Platforms like NPTEL, Coursera, or edX offer beginner-friendly CFD courses. Some engineering colleges in Odisha have also begun integrating these tools into their regular curriculum, which is a big plus.

How to Practice What You Learn

Theory alone won’t make you a CFD expert. Try to:

Take up mini projects: Simulate airflow over an airfoil, or cooling in an electronics system.

Participate in competitions: Some colleges encourage participation in technical fests and simulation challenges.

Intern with companies: Many industries use CFD daily. A short internship can give you exposure to real-world applications.

Which College Can Support Your CFD Learning?

If you're serious about CFD, the environment you study in matters. Look for institutes that offer strong lab facilities, experienced faculty, and industry collaboration. Some of the best engineering colleges in Odisha include departments that focus on mechanical, civil, and aerospace disciplines—all key areas where CFD is relevant.

During my interactions with students from various institutes, I’ve noticed that colleges like NMIET provide access to digital labs, industry tie-ups with companies like IBM and Cognizant, and even R&D opportunities. These are the things that matter when you want to get practical exposure alongside theory.

Final Thoughts: CFD Is a Journey, Not a Shortcut

It’s okay if CFD feels overwhelming at first. It’s a complex field that blends physics, math, and computer science. But the good news? With consistent effort, curiosity, and the right guidance, anyone can learn it.

Whether you're a first-year student just discovering the world of engineering or a senior looking to specialize, starting your CFD journey today can open up exciting opportunities in both academia and industry.Remember, tools can be learned—but the mindset to explore, question, and simulate the real world? That’s something you start building now. And if you’re studying at one of the best engineering colleges in Odisha, you already have a head start.

#bhubaneswar b tech colleges#college of engineering bhubaneswar#best engineering colleges in orissa#best engineering colleges in bhubaneswar#best private engineering colleges in odisha#best engineering colleges in odisha

0 notes

Text

Primary investigation on ram-rotor detonation engine

Detonation is a supersonic combustion wave, characterized by a shock wave driven by the energy release from closely coupled chemical reactions. It is a typical form of pressure gain combustion, converting chemical energy into thrust efficiently. The concept of harnessing detonation to improve thermodynamic cycle efficiency and enhance the performance of aerospace propulsion systems has been a subject of interest for many years. Since the 1950s, various types of detonation engines have been proposed, including pulse detonation engines, oblique detonation engines, and rotating detonation engines. However, these three types of detonation engines encounter challenges such as poor thrust continuity, high starting Mach numbers, and insufficient performance gains, which limit the widespread application of detonation propulsion technology.

In a recent article featured in the Chinese Journal of Aeronautics, Dr. Haocheng Wen and Prof. Bing Wang from Tsinghua University proposed a new concept for detonative propulsion, called the Ram-Rotor Detonation Engine, which is expected to break through the limitations of the above-mentioned detonation engines.

“The original intention of developing this new engine is to improve the structures of rotating detonation engines,” said Dr. Haocheng Wen, “this concept is also inspired by the ram-rotor compressor.” The ram-rotor detonation engine, abbreviated as RRDE, mainly consists of a rotating rotor with blades, and a stationary casing. The blades on the rotor are distributed in a helical symmetric manner. The combustible mixture undergoes compression, detonation combustion, and expansion within the variable cross-sectional channels between the blades.

The authors performed primary theoretical and numerical investigation on the RRDE. They established a theoretical model to analyze the relationship between the propulsion performance and parameters such as inlet velocity, rotor rim velocity, and equivalence ratio. It is indicated that for the stoichiometric hydrogen/air mixture, the total pressure gain of RRDE can exceed 3. Furthermore, they also conducted numerical simulations on the typical structure of RRDE and obtained the characteristic flow field and propulsion performance of engine. Their simulation results demonstrate that the detonation wave can stabilize and remain stationary within the blades by the given configuration, and can adapt to the variations in parameters such as the equivalence ratio within a certain range. “Our study primarily verifies the performance benefits and operation feasibility of the RRDE.” said Dr. Haocheng Wen.

The authors believe that the RRDE has several advantages, including a simple and compact structure, high efficiency, and the adaptability to a wide-range of flight Mach number. However, they also candidly acknowledge that the realization of the RRDE is confronted with numerous challenges that demand resolution, such as the stabilization mechanism of detonation wave, supersonic boundary layer interference, implementation of high-speed rotor, as well as thermal protection, etc. “Our team is conducting ongoing research on key scientific and engineering issues in RRDE.” said Prof. Bing Wang. They expect the RRDE can provide high-performance propulsion for the supersonic vehicles in the future.

IMAGE: Conceptual scheme of a supersonic vehicle using the ram-rotor detonation engine Credit Chinese Journal of Aeronautics

4 notes

·

View notes

Text

Engine Component Manufacturing and New Machining Services: Precision for Modern Performance

A high-performance vehicle, aircraft, or industrial machine starts with its engine components. The evolution of engine component manufacturing has been driven by the need for tighter tolerances, improved materials, and higher durability. Today, the industry is embracing new machining services to meet growing demands for speed, precision, and efficiency. CNC machining and additive manufacturing are among the new technologies changing how we produce engine parts. This blog explores SYRONTECH's key aspects of engine component manufacturing and the latest machining services that are shaping the future.

The Importance of Engine Component Manufacturing

Pistons, crankshafts, cylinder heads and valves all face harsh pressures and temperatures when they are in use. Building modern engines relies on very strong valves, do not wear easily and are perfectly matched. They are made using set tools, require top-quality resources and are overseen by strong quality control measures. Machining mistakes as small as a few microns may result in failure or a loss of efficiency for engines. For this reason, precision must be included, not just chosen at will. The individual quality of each component helps to determine the engine’s overall performance.

Materials Used in Engine Components

Modern engineers use different advanced materials to build engine parts. Aluminum alloys are often used because they are lightweight and are found in car engines. Both steel and cast iron are popular for their good strength and ability to resist wear in tough engines. Heat resistance and low weight have made it possible for titanium and ceramic composites to find use in aerospace engine construction. Every material needs unique work methods, its tools, and special cooling during machining. It is important to use the right material for the engine’s better performance.

Traditional vs. Modern Machining Techniques

For decades, turning, milling, grinding and drilling have been common ways to make parts for engines. They get the job done, yet they take longer and are not suited for complex shapes. New Machining Services now use CNC (Computer Numerical Control) machines for higher precision and repeatability. CNC systems automate the cutting process based on digital models, reducing errors and production time. Multi-axis CNC machines can create intricate shapes that were once impossible to achieve. These new methods are faster, more efficient, and ideal for complex engine designs.

CNC Machining in Engine Component Production

CNC machining is revolutionizing the manufacturing of engine components. It allows manufacturers to produce complex parts with high accuracy and tight tolerances. With 3-axis, 4-axis, and 5-axis capabilities, CNC machines can perform multiple operations in a single setup. This improves consistency and reduces material waste. For example, CNC milling can produce cylinder heads with intricate cooling channels, while CNC turning can precisely shape crankshafts and camshafts. The use of CAD/CAM software enhances the design and simulation process before production begins.

Additive Manufacturing for Prototyping and Small Batches

Additive manufacturing, or 3D printing, is gaining popularity in engine component development. It’s ideal for prototyping and producing small batches quickly without the need for custom tooling. Engineers can test different designs before mass production, reducing time and cost. For example, metal 3D printing is used to create turbocharger components and heat exchangers with complex internal structures. Although not yet common for mass production, additive manufacturing is valuable for innovation and design flexibility in engine development.

Surface Finishing and Coating Technologies

Surface finishing is crucial to engine component performance. After machining, parts often require polishing, honing, or coating to improve durability and efficiency. Surface treatments like nitriding, chrome plating, or ceramic coatings enhance hardness, reduce friction, and resist corrosion. These processes are especially important for moving parts like pistons and valve stems. Automated finishing systems ensure uniformity and reduce the risk of human error. The right finishing technique extends the lifespan of engine components and supports reliable engine operation.

Conclusion

The future of engine component manufacturing lies in precision, speed, and innovation. New machining services like CNC, additive manufacturing, and automation are enabling the production of smarter, stronger, and more efficient engine parts. Material science and surface finishing techniques are also evolving to meet modern performance demands. Whether in automotive, aerospace, or industrial sectors, these advancements are helping engineers push the boundaries of engine design. For companies like SYRONTECH, investing in next-generation machining services, the road ahead is full of opportunity and growth.

#Engine component manufacturing#CNC machining#additive manufacturing#3D printing#surface finishing#SYRONTECH#engine parts#precision machining#aerospace engine components#automotive engine parts.

1 note

·

View note

Text

Quantum Technology Playing Larger Role in Foreign Militaries

According to U.S. Defence Intelligence, countries are employing quantum technologies more. The U.S. Defence Intelligence Agency's (DIA) 2025 Worldwide Threat Assessment warns that adversaries are cooperating and increasing cyber threats against U.S. interests and vital infrastructure, while quantum technologies are approaching operational military use. Due to significant advances in quantum science, AI, microelectronics, and cyber capabilities, the report claims that modern warfare is changing.

Fast Quantum Development Quantum is now part of China and Russia's active defence strategy, according to the DIA assessment. Quantum computing's potential to overcome encryption has received attention, but the DIA believes quantum sensors are more practical. Since they can detect magnetic or gravitational forces, these sensors may be able to locate submarines or subsurface structures without satellites. Such capabilities could boost situational awareness, especially in places with weak or blocked GPS signals.

Quantum-secure communications have advanced beyond sensing. China's national quantum network is evolving with numerous city-spanning lines using quantum key distribution (QKD), a technique claimed to be immune to current eavesdropping. Russia may also be funding secure quantum links with national defence and research organisations. Despite its transformative potential, quantum computing poses a longer-term threat. Although quantum computers aren't widely available, algorithmic advances may reduce the resources needed to attack private data. The number of quantum bits (qubits) needed to breach RSA encryption may be an order of magnitude lower than previously assumed, while the practicality and physicality of such attacks are unknown. Some quantum computer systems have manufacturing, stability, and error correction issues, and most military applications still require huge, power-intensive quantum sensing devices. The evaluation concludes that quantum technologies are gradually entering vital systems and providing benefits like faster target recognition, unbreakable communications, and more accurate navigation that meet the demands of modern, networked warfare. Microelectronics and Convergence: Future Threats

These technological advances together strengthen them. According to the research, quantum technologies are emerging alongside advanced manufacturing, artificial intelligence, and electronic warfare to accelerate their adoption into military systems. These combinations allow countries to research quantum computers for signal analysis, logistics, and multi-domain simulations by linking sensors, secure communications, and AI-driven decision frameworks. This technological competition relies on advanced microelectronics. The DIA emphasises that chips and fabrication capacity are critical chokepoints to technological rivalry. Computing-intensive technologies like quantum and AI require high-end microelectronics. Even while the US and its allies have an advantage in production and design, competitors are actively striving to reduce their dependence on foreign supply. Despite export limitations hindering China's growth in various disciplines, domestic funding and foreign workarounds appear to be maintaining quantum technology research. Despite sanctions-induced supply constraints and cost pressures, Russia prioritises electronics for missiles and secure communications. Evolving Cyberthreats

Increased state and non-state cyber activities also affects the danger landscape. The analysis found that enemies are seeking new ways to threaten US infrastructure and cyber networks. Cyber Focus: China restructured their military to prioritise cyber and electronic warfare as asymmetric weapons, placing Aerospace, Cyberspace, Information Support, and Joint Logistic Support Forces under the Central Military Commission. China wants to challenge US space dominance by improving C5ISRT. Chinese hackers, notably the PLA Cyberspace Force and Ministry of State Security, steal data and intellectual property from global networks, including US government networks. China will likely continue to use its cyber capabilities to gather intelligence on political, military, economic, and intellectual targets and steal secret data for military and economic advantage. Since early 2024, the U.S. government has publicly listed Chinese cyber operators planning to strike U.S. essential infrastructure if a major conflict arises. Russia's Asymmetric Approach: Russia can avoid NATO confrontation by using cyber and media assaults. Russian state and non-state cyber groups continue to assault US-connected networks. States prioritise espionage, and one gang, apparently associated with the Russian Foreign Intelligence Service (SVR), stole terabytes of Microsoft data, including U.S. government account information. Low-level attacks on energy and water networks by pro-Russian non-state hackers have increased since 2023, compromising public safety and national security. Russia will likely use proxies, cyber, media, and covert action in response to Western support for Ukraine. North Korea and Iran: North Korea uses cyberspace for espionage and financial gain to avoid sanctions. It uses ransomware, cryptocurrency theft, and hacking-for-hire. It also gathers weapons-development intelligence from foreign academics, defence industry personnel, and politicians, often using international criminal networks. Iran has expanded cyberattacks, cyberespionage, and information operations against Israel to aid its regional proxies. Geopolitical cooperation strategic implications

These technological and cyber achievements reflect China and Russia's growing military and technical partnership and relations with North Korea and Iran, according to the research. China cooperates in training and technological exchanges but avoids military aid. Some Russian nuclear and space technology is used for navigation and quantum sensing, according to reports. To avoid American influence, enemies are cooperating more. These trends strategically affect US defence. The research says defence strategy must now include quantum preparation, extending beyond cybersecurity to assess how quantum clocks and sensors may challenge detection, stealth, and navigation assumptions. This is a big difference from past appraisals that saw quantum as a long-term study. Quantum technologies may be difficult to identify and evaluate before deployment, creating technical surprise. This reduces warning time and complicates intelligence gathering. If competing quantum capabilities are not benchmarked and monitored, the US may be acting on outdated assumptions. Finally, commercial and academic partnerships in quantum science with Chinese government-backed organisations may not align with U.S. interests, and research results may be used for military purposes, emphasising the need for export controls and secure research environments.

#quantumtechnology#quantumtech#quantumsensors#quantumtechnologies#QuantumCyberThreats#DefenseIntelligenceAgency#technology#technews#technologynews#news#govindhtech

0 notes

Text

Revolutionize Your Manufacturing with CAM2: Precision, Performance, and Power

In today’s competitive manufacturing landscape, precision and speed are everything. Whether you're working in automotive, aerospace, or heavy machinery, delivering high-quality components within tight timelines can make or break your business. That’s where CAM2 solutions from DDSPLM come in bridging the gap between design and production with unparalleled control, flexibility, and efficiency.

What is CAM2?

CAM2 (Computer-Aided Manufacturing) is a powerful module from Siemens Digital Industries Software, designed to optimize NC (Numerical Control) programming for milling, turning, and multi-axis machining operations. Built as an extension of Siemens NX, CAM2 enables seamless integration between product design and machining processes, ensuring that what you design is exactly what you manufacture with minimum error, time, or material waste.

Key Features of CAM2

Here are the standout features that make CAM2 a must-have in your digital manufacturing toolbox:

Seamless Integration with Siemens NX

Comprehensive Toolpath Generation

Postprocessor Customization

Simulation and Verification

Tool Library Management

Automated Feature Recognition

Adaptive Machining Strategies

Cloud Collaboration

Benefits of CAM2

Implementing CAM2 in your manufacturing process offers numerous benefits:

Improved Production Accuracy

Faster Time-to-Market

Lower Operational Costs

Better Resource Utilization

Scalability for Complex Projects

Enhanced Collaboration

Why Choose DDSPLM?

At DDSPLM, we don’t just provide software — we provide solutions. Here's why CAM2 through DDSPLM is your best decision:

Expert Implementation Support

Certified Training & Workshops

Post-Sales Service & Support

Proven Industry Experience

Consulting & Process Optimization

Conclusion